Origin of wastewater from carton packaging production

- Wastewater containing printing ink generated during the production process

- Wastewater washing production machinery and equipment, factory floors…

- Hospital staff’s daily activities such as: eating, cleaning, bathing, laundry.

- Wastewater for sanitation, cleaning…

Composition and properties of paper packaging production wastewater

Wastewater generated during the factory’s production and daily activities is one of the deep concerns and concerns for environmental and social managers because it can cause serious environmental pollution and dangerous to human life.

The main components causing environmental pollution caused by wastewater are:

- COD content

- Organic matter, color ….

- Nutrients of nitrogen (N), phosphorus (P)

- Suspended solids

- Germs and bacteria that cause disease.

Organic pollutants and color in wastewater (about 55-65%) will reduce the amount of dissolved oxygen in the water, affecting the life of aquatic animals and plants.

Nutrients of N and P cause eutrophication of sources receiving wastewater, affecting living organisms in the aquatic environment.

Suspended solids cause water turbidity, creating sediment deposits that clog drains, pipes and drains. But organic substances in wastewater are easily biodegradable.

The content of decomposed organic matter is determined indirectly through the biochemical oxygen demand (BOD) of wastewater.

Characteristics of wastewater from Carton paper packaging production

| STT | Target | Unit | Value |

| 01 | pH | – | 5 – 9 |

| 02 | BOD | mg/l | 1500 -2000 |

| 03 | TSS | mg/l | 800-1200 |

| 04 | COD | mg/l | 2000 -3000 |

| 05 | Total nitrogen | mg/l | 200 -400 |

| 06 | Color | Co-Pt | 500-800 |

| 07 | Coliform | MPN/100ml | 1 ´ 107 |

Design requirements for paper packaging wastewater treatment systems

The design and installation of a wastewater treatment system not only must ensure compliance with regulatory standards, but must also ensure elements that take up little space, are easy to install, operate and maintain, and do not cause secondary pollution that affects the environment. affect the surrounding environment.

The treatment station must also have the cost of installing technological equipment and treatment products must be suitable, with high productivity and stable operation.

The wastewater treatment system is designed to meet the requirements for post-treated wastewater QCVN 40:2011/BTNMT Column B – National standards on industrial wastewater

Table 2: Post-treatment wastewater requirements

| STT | Target | Unit | Value (QCVN 40 : 2011/BTNMT, Column B) |

| 01 | pH | – | 5.5– 9 |

| 02 | BOD | mg/l | 30 |

| 03 | TSS | mg/l | 100 |

| 04 | Color | mg/l | 150 |

| 05 | Total Nitrogen | mg/l | 40 |

| 06 | COD | mg/l | 150 |

| 07 | Coliform | MPN/100ml | 5,000 |

The wastewater treatment plan selected depends on the specific conditions of the Project and the treatment satisfies the following requirements:

- Does not make noise, does not cause unpleasant odors to the surrounding area.

- Does not affect the aesthetics and general operations of the factory

- Simple management and operation, reasonable operating costs.

From the above characteristics and the requirements to be achieved after treatment, wastewater treatment technology includes the following main steps:

Step 1: Use mechanical methods to remove large substances suspended in water and neutralize them.

Step 2: Use physicochemical methods to treat organic substances, COD, N, P, color… of wastewater

Step 3: Use anoxic combined aerobic biodegradation method to remove organic substances present in wastewater. Aims to continue to reduce nitrogen and organic pollutant content in water (COD; BOD)

Step 4: Use disinfection method to kill harmful microorganisms in water. Ensure the output water meets discharge standards QCVN 40:2011/BTNMT Column Bfor industrial wastewater

Step 5: Sewage sludge will be pumped to the sludge tank and periodically sucked.

Explanation of paper packaging wastewater treatment technology diagram

Wastewater generated during production and daily life (wastewater from production activities, cleaning equipment, washing floors, eating…): This wastewater flow after that has passed through the local oil and grease separation system and septic tank will be collected into the treatment system into the collection tank. Before entering the wastewater collection tank, it must pass through a garbage separator with a gap of 2-4mm to avoid causing damage. clogging the wastewater pump in the tank and protecting equipment for the rear unit works. Wastewater in the collection tank will be pumped through the equalization tank to begin the treatment process

– The wastewater in the conditioning tank is regulated in flow and stabilizes the concentration of pollutants, helping the downstream treatment process achieve the highest efficiency. At the wastewater conditioning tank, the wastewater is transported by 02 submersible pumps that work alternately to pump through the flocculation tank

– At the flocculation tank the process of adding oppositely charged ions (positive charge) occurs to neutralize the charge of the colloidal particles in the water, increasing the zeta potential, breaking particle durability, preventing the chaotic movement of ions in water. The chemicals used for the flocculation process are PAC and NaOH and there is stirring of the stirring motor to enhance the performance of the flocculation process of pollutants, nitrogen, phosphorus, COD, organic substances, suspensions, etc. Phew…

Factors affecting the flocculation process that we need to consider are:

- Effect of pH

- Water temperature

- Type and concentration of coagulant and flocculation aid

- Stirring speed

- After flocculation, the wastewater flows through gravity through the flocculation tank

–In the flocculation tank, the process of linking the flocs together after the flocculation process occurs under the influence of stirring at a small speed to increase the size and volume of the flocs. residue so that the flocs can easily settle.

Factors affecting the flocculation process: pH, temperature, stirring speed

After flocculation, wastewater will flow by gravity to the physicochemical settling tank

Chemical metering pump system for paper packaging wastewater treatment

–At the physical and chemical sedimentation tank the chemical flocs during the flocculation process and organic residues will settle and be sucked through the sludge tank. Clean water after passing through the foam barrier and serrated trough will flow gravity through the neutralization tank. Sludge generated during the physical and chemical treatment process will be periodically sucked up by a functional unit. The wastewater will then continue to flow through the anoxic biological tank.

– In the anoxic biological tank wastewater is mixed by a submersible mixer to create an anoxic environment for microorganisms to operate and best process organic compounds and nitrates. In the anoxic compartment, wastewater containing activated microbial sludge is circulated from the aerobic tank to ensure the best treatment time and environment.

+ The process of Nitrate reduction occurs as follows: In an oxygen-deficient environment, these bacteria will reduce Nitrate. Denitrificans will separate the oxygen of Nitrate (NO3-) and Nitrite (NO2-) in a chain of conversion. chemistry:

NO3– → NO2– → N2O → N2↑

Gas Nitrogen the N2 molecules formed will escape the water and go outside.

Wastewater from the Anoxic anoxic tank will flow gravity through the aerobic biological tank

– At the aerobic biological tank suspended aerobic microorganisms will use toxic organic substances in the water, BOD, ammonium and total nitrogen… as a food source and to synthesize energy. living. In the Aerobic tank, wastewater is mixed with activated microbial sludge, air is provided from 2 air blowers that operate alternately 24/24 hours throughout the tank area, providing oxygen, creating an oxygenated environment. dissolve > 2mg/l is favorable for aerobic microorganisms to grow and decompose pollutants. Microorganisms will decompose organic substances into final products CO2 and H2O, reducing the concentration of dirt in wastewater.

The aerobic biological tank is the unit that determines the treatment efficiency of the system because most of the pollutants in wastewater are organic substances that are easily biodegradable.

The aerobic biological treatment process of wastewater includes the following stages:

Oxidation of organic substances:

CxHyOz + O2 (xt Enzyme)–> CO2 + H2O + ΔH

- Synthesis of new cells

CxHyOz + NH3 + O2 –> CO2 + H2O + C5H7NO2 + ΔH

Intracellular degradation:

C5H7NO2 + 5º2 (xt Enzyme)–> 5CO2 + H2O + NH3 ± ΔH

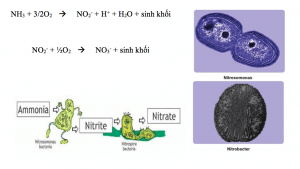

In addition, the group of autotrophic microorganisms Nitrosomonas and Nitrobacter use nitrogen and phosphorus to metabolize nitrate and create biomass.

In addition, the group of autotrophic microorganisms Nitrosomonas and Nitrobacter use nitrogen and phosphorus to metabolize nitrate and create biomass. Nitrification occurs according to the following reaction equations:

Phosphoritization process: Organic compounds containing phosphorus will be converted by Acinetobacter bacteria into new compounds that do not contain phosphorus and compounds that contain phosphorus but Easily decomposed by aerobic bacteria. Wastewater from the aerobic tank flows through gravity through the biological sedimentation tank.

– At the biological sedimentation tank water will be separated from sludge. The microbial sludge will settle to the bottom and be pumped back to the anoxic biological tank. The excess sludge will be pumped to the biological sludge tank and periodically sucked by a functional unit. Clean water from the biological sedimentation tank after passing through the foam barrier and serrated trough will flow gravity through the disinfection tank.

– At the disinfection tank disinfectant chemicals will be pumped in to kill microorganisms in the water. Ensure output wastewater after treatment meets column B, QCVN 40:2011/BTNMT for industrial production wastewater

Wastewater treatment system for paper packaging containing printing ink water was installed by Nam Viet

Advantages of wastewater treatment technology for paper packaging production

With the above technological process, the combined use of physicochemical technology and biological technology in paper packaging wastewater treatment is being widely applied in other countries and around the world, bringing very high treatment efficiency. . In addition, the system also has the following outstanding advantages:

- Physicochemical treatment process: is the process of treating COD, Nitrogen, phosphorus, synthetic organic matter, color… in wastewater with high treatment efficiency thanks to neutralizing chemicals, flocculation, flocculation, sedimentation… and proper mixing process of mixing motors, temperature, pH of wastewater…

- Biological treatment process: is the process of treating BOD, Nitrogen, phosphorus, and synthetic organic matter. In particular, the processes of nitrification and denitrification occur continuously in biological tanks. The denitrification process uses hydrocarbon sources available in wastewater, limiting the growth of filamentous bacteria and reducing caking and difficulty settling in sedimentation tanks.

- The Nitrate reduction process occurs, raising the pH and alkalinity of the wastewater, creating oxygen to facilitate the subsequent nitrification process, reducing the amount of gas needed for the nitrogen treatment process;

- Aerobic tanks have a high density of microorganisms per unit volume, so the organic matter load is high, thus the efficiency of organic matter treatment is higher and the ability to withstand shock loading is high. At the same time, due to high microbial density, the possibility of sludge generation is low

- Physical and chemical technology combined with biology is the most effective wastewater treatment technology today with the most reasonable investment cost.

- The system operation process is fully automatically controlled, which eases operational work, saves electricity costs, ensures the quality of treated water is always stable and meets discharge requirements.

Nam Viet Environmental Engineering Joint Stock Company specializes in treating dropped wateri water supply, customers who need advice or quotes please contact Hotline 0932562177

Bài viết liên quan

UASB tank in wastewater treatment

Introducing the UASB tank UASB stands for Upflow Anaerobic Sludge Blanket, roughly translated as reverse...

Common Aerotank tank problems and how to fix them

Aerotank incidents during the operation of the WWTP often arise equipment problems such as pumps,...

Oxidation ditch in wastewater treatment

What is an oxidation ditch? Oxidation ditch is an improved form of complete mixing aeroten...