Introducing the Unitank tank

The simplest structure of a Unitank tank is a rectangular tank divided into 3 compartments, these 3 compartments are interconnected by an opening in the common wall. In each compartment there is a surface aerator and a stirrer. The two outer compartments have an additional overflow trough system to perform both functions: also a tank Aeroten (aeration) and settling tank. Wastewater is put into each compartment. The treated water flows out through the trough; Excess biological sludge is also removed from the system from two outer compartments.

Operating principle of the Unitank tank

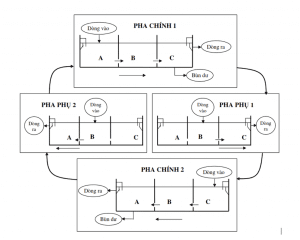

The first main phase of the Unitank tank:

Wastewater is loaded into compartment A. At this time compartment A is aerated. Incoming wastewater will be mixed with activated sludge. Organic compounds are partially absorbed and decomposed, a process called accumulation. From compartment A, the liquid sludge mixture (water + sludge) flows through compartment B and continues to be aerated. The sludge will decompose the organic substances absorbed in compartment A, a process called regeneration.

Finally, the liquid sludge mixture reaches compartment C, where there is no aeration and no stirring. In still conditions, the sludge particles settle by gravity, while the clear water is collected by the overflow trough. Excess biological sludge is removed in compartment C. to avoid attracting sludge from A, b and accumulating in C. The flow direction changes after 120 – 180 minutes (phase change).

The first intermediate phase is the Unitank tank

Each main phase is followed by an intermediate phase. The function of this phase is to convert the aeration compartment into a sedimentation compartment. Wastewater is loaded into compartment B and both compartments A and C are in the settling process. During this time, the next main phase (with opposite flow direction) is prepared, ensuring good separation and clean effluent.

The second main phase of the Unitank tank

This phase is similar to the first main phase but with reverse flow, the wastewater is loaded into compartment C, flows through B to A. Compartment A now acts as the settling compartment (no aeration, no agitation).

The second intermediate phase is the Unitank tank

This phase is the opposite of the first intermediate phase, the aeration compartment C will now turn into the sedimentation compartment while compartment A is at the end of the settling process and compartment B is aerated, this phase prepares the system to enter the settling phase. first and start a new cycle.

The operation of the tank includes 2 main phases and 2 intermediate phases.

Advantages of Unitank tanks

- Because the treatment and sedimentation process are in the same tank, costs are saved and space is saved;

- The on-site sedimentation process does not require suctioning out the sludge, so biomass can be adjusted for the next operation;

- Unitank’s batch aeration and sedimentation process has the advantage of easily adjusting the treatment process and being able to remove nitrogen and phosphorus.

Disadvantages of Unitank tanks

- If water collection troughs are used in compartments A and C, during the aeration process, the mixture of sludge and wastewater flows into the collection trough, so the initial water discharge phase will carry a small amount of sediment;

- Collecting excess sludge is difficult because the tank bottom is flat and the sludge concentration is thin

Nam Viet Environmental Engineering Joint Stock Company specializes in consulting, design, construction and installation of wastewater treatment systems, water supply, and chemicals boiler. If you need consulting support or a quote, please contact Hotline 0932562177

Bài viết liên quan

Download QCVN 01-1:2024/BYT – Quy chuẩn kỹ thuật quốc gia mới nhất về chất lượng nước sinh hoạt

1. QCVN 01-1:2024/BYT là gì? QCVN 01-1:2024/BYT là quy chuẩn kỹ thuật quốc gia do...

Tác hại của xả rác đối với môi trường và sức khỏe con người

Xả rác bừa bãi đã trở thành một vấn nạn nghiêm trọng, ảnh hưởng tiêu...

Than Hoạt Tính và Ứng Dụng Trong Xử Lý Nước Cấp Nước Thải

Than hoạt tính từ lâu đã được biết đến như một giải pháp hiệu quả...