What is an oxidation ditch?

Oxidation ditch is an improved form of complete mixing aeroten working in prolonged aerobic conditions with activated sludge (suspended growth of microorganisms in wastewater) circulatory movement in the ditch. Wastewater with high contamination BOD20 = 1000-5000mg/L can be treated with oxidation ditches.

- Characteristics are as follows:

- The cross-section of the ditch can be rectangular (reinforced concrete ditch), trapezoidal (earthen ditch covered with stone), the slope of the slope (m) on both sides depends on the strength of the soil, usually m ≤ ½

- The depth H of the ditch depends on the pumping capacity of the aeration device to ensure even mixing of air bubbles and create a circulating velocity along the ditch V ≥ 0.25- 0.3m/s, you can choose H = 1 ÷4m.

- The average width of the ditch is from 2 to 6m.

In places where there is not enough length and ditches are arranged in a zigzag pattern, in the area at both ends of the ditch, when the water flow changes direction, the water flow speed is fast on the outside and slow on the inside, causing the mud to settle, reducing the effectiveness of the ditch. processing results. Therefore, it is necessary to build flow direction walls at both ends of the ditch to increase the water speed inside

General principles of chemical ditches

This process technology is based on “suspended” biological growth called “activated sludge” maintained in an oxygen-rich environment, this biological growth is very rapid and destroys organic matter present in wastewater input. This destruction causes a large volume of dead cells, increasing the volume of activated sludge solids.

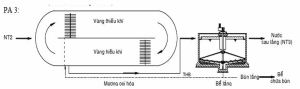

After remaining in the oxidation ditch for about 24 hours, the activated sludge and combined wastewater – often called “mixed liquid” are transferred to the secondary sedimentation tank to separate from the treated effluent. and sludge. Part of this sludge is recirculated to the wastewater inlet into the oxidation ditch and returned to activated sludge, further destroying the organic BOD5 load.

The remainder of this settled sludge is discharged into a thickening process followed by a dewatering step in the process of removing the remaining sludge from the factory site.

Unlike the traditional activated sludge process, there is no specific requirement for primary sedimentation tanks as the first stage treatment process, as the raw wastewater input can be directed directly to the oxygen raceways. chemical for processing.

For domestic wastewater, it only needs to go through the trash screen, sand sedimentation, and without going through sedimentation, it can be put into the oxidation ditch. The load of the oxidation ditch is calculated based on activated sludge based on about 200g BOD5/kg.day. Part of the mud is mineralized right in the ditch. Therefore, the amount of sludge is reduced by about 2.8 times. Aerobic treatment time is 1-3 days.

Classification of oxidation ditches

There are two types of oxidation ditches:

- The oxidation ditch is built of reinforced concrete

- Oxidation ditch dug in the ground: the inside surface is covered with stone, cement or asphalt

Technological process and cases of applying oxidation ditches

Because the oxidation ditch effectively treats BOD5, Nitrogen, is simple to manage, has a large volume, and is less affected by large fluctuations in the quality and flow of treated water. is applied to wastewater treatment in places where in addition to treating BOD, it is also necessary to treat Nitrogen and phosphorus and there are large fluctuations in flow and quality between hours of the day.

Nitrogen treatment by oxidation ditch includes nitrification and denitrification process.

- The nitrification process takes place in the aerobic zone as follows:

Under the influence of Nitrosomonas and Nitrobacter, nitrification occurs according to the following reaction equations:

NH3 + 3/2O2 -> NO2– + H+ + H2O + biomass : Nitrosomonas

NO2– + ½O2 -> NO3– + biomass: Nitrobacter

- The denitrification process takes place in the anoxic zone as follows:

- Assimilation process:

3NO3– + 14CH3OH + CO2 + 3H+ -> ; 3C5H7O2N + H2O

- Catabolic process:

Step 1: 6NO3– + 2CH3OH -> 6NO2– + 2CO2 + 4H2O

Step 2: 2NO2– + 3CH3OH -> 3N2 + 3CO2 + 3H2O + 6OH–

————————————————– ———-

6NO3– + 5CH3OH -> 5CO2 + 3N2 + 7H2O + 6OH–

Advantages and disadvantages of oxidation ditches

| ADVANTAGES | DISADVANTAGES |

| Trusted technology | Consumes electricity |

| Good nitrogen handling ability | Limited biological phosphorus processing capacity |

| Less complicated to operate | Consumes land area |

| Resistant to shock loads | Need regular attention to measuring equipment to check graduations and repairs |

| No need for settling tank I | |

| No need for mud stabilization works |

Nam Viet Environmental Engineering Joint Stock Company specializes in consulting, design, construction and installation of wastewater treatment systems, water supply, and chemicals boiler. If you need consulting support or a quote, please contact Hotline 0932562177

Bài viết liên quan

UASB tank in wastewater treatment

Introducing the UASB tank UASB stands for Upflow Anaerobic Sludge Blanket, roughly translated as reverse...

Wastewater treatment of carton paper packaging production

Origin of wastewater from carton packaging production Wastewater containing printing ink generated during the production...

Common Aerotank tank problems and how to fix them

Aerotank incidents during the operation of the WWTP often arise equipment problems such as pumps,...