Industrial RO water filtration systems have been around for more than 50 years in the world and are widely used in industrial production. In Vietnam, along with the development of the economy, in recent years RO technology has also been very popular because of the effectiveness it brings.

Concept of industrial RO water filtration.

- RO stands for Reverse Osmosis. Where Reverse: reverse; Osmosis: osmosis -> So we can understand RO: Is water filtration according to the principle of Reverse Osmosis.

- Industrial: refers to high-capacity filtration systems, distinct from household RO water purifiers.

The reason why RO is called reverse osmosis

- Osmosis: Water moves from low concentration to high concentration.

- Reverse Osmosis: Water passes from a high concentration area to a low concentration area.

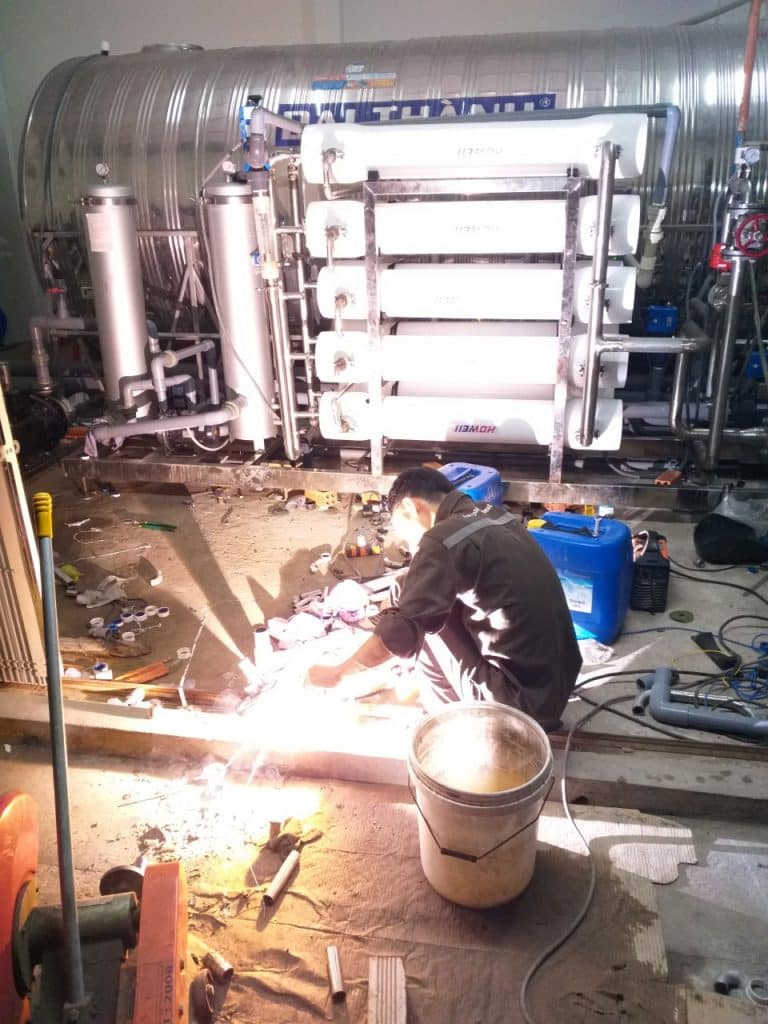

RO water filtration system designed by Nam Viet

History of industrial RO water filtration system

- The process of osmosis through semi-permeable membranes was first discovered in 1748 by Jean-Antoine Nollet.

- For the next 200 years, osmosis was only a laboratory phenomenon, with no application.

- In 1950, the University of California at Los Angeles first studied the desalination process of seawater using semi-permeable membranes.

- Researchers from the University of California at Los Angeles and the University of Florida successfully produced fresh water from seawater in the mid-1950s, but the flow rate was too low to be commercially viable.

- Subsequent research at the University of California by Sidney Loeb and Srinivasa Sourirajan at the National Research Council of Canada, Ottawa, on asymmetric membrane forming techniques characterized by an effective thin layer of “membrane” supported on the highly porous and much thicker substrate region of the membrane.

- John Cadotte, of FilmTec Corporation, discovered that membranes with exceptionally high flux and low salt passage could be produced by surface polymerization of m-phenylene diamine and trimesoyl chloride.

- Almost all commercial reverse osmosis membranes today are made using this method.

- By 2019, there were approximately 16,000 desalination plants operating around the world, producing approximately 95 million cubic meters per day (25 billion US gallons per day) of desalinated water for human consumption. About half of this capacity is in the Middle East and North Africa region.

Operating principle of industrial RO membrane

- Reverse osmosis removes contaminants from water, Water flows from the more concentrated medium (more dirt) of the RO membrane to the less dense (less dirt) side to produce cleaner, purified water than.

- The fresh water produced is called the permeate, the remaining concentrated water is called the discharge stream or brine.

- Semi-permeable membranes have small holes that only water molecules flow through while water-soluble substances are retained, this is the reason the waste stream has a more concentrated salt content.

- Semi-permeable membranes remove 98% of dissolved solids

Filtration performance of industrial RO membranes

- Very high filtration efficiency removes 90-98% of TDS content in water.

- Eliminates bacteria and viruses in water

- Produces good water quality on industrial scale.

- Water can be drunk directly

- Treat saline water into fresh water.

- What can be eliminated?

- Fluoride? Have

- Salt? Have

- Sediment? Have

- Chlorine? Have

- Arsenic? Have

- VOCs? Have

- Herbicides and pesticides? Have

- Bacteria and viruses? RO membrane can remove Bacteria and viruses. However, during operation, bacteria can form on the membrane and enter the water, so we recommend installing UV light disinfection.

To better understand the structure of an industrial RO water filtration system, please see more here

- Coarse filter: Use a multi-stage filter column to remove suspended solids 10 micrometers in size, iron alum, heavy metals, etc.

- Activated carbon filter: Reduces volatile organic compounds (VOCs), other contaminants that cause water to have an unpleasant taste, absorbs residual chlorine to protect the filter membrane.

- Soften: Remove stiffness mainly Ca2+ and Mg2+, to avoid membrane blockage

- Fine filtration: Removes impurities as small as about 5 micrometers

- RO: only allows water molecules to pass through, leaving the impurities of mineral salts, heavy metals… all trapped and going out through the discharge line.

Nam Viet Engineering installs industrial RO water filtration systems at customers

Classification of industrial RO water filtration membranes

- Membrane for fresh water: TDS <1000 mg/l

- Membrane used for brackish water: TDS 1000-10,000 mg/l

- Membrane for salt water: TDS 10,000-30,000 mg/l

In what industries is the industrial RO water filtration system applied?

- Filter drinking water

- Food industry

- Industrial production

- Medical

- Run the boiler and turbine to generate electricity

- Desalination

- Wastewater treatment…

Advantages of industrial RO water filtration system installed by Nam Viet ETC

- Operates almost completely automatically, easy to control.

- Backwash and regeneration modes are performed using pre-installed programs.

- Indicators are controlled by strict online probes.

- Output water quality is guaranteed to meet requirements.

- When the system has an unsatisfactory output water quality problem, the online measurement system will automatically alarm and close the output, sending water back to the intermediate tank for filtering and reprocessing.

Some industrial RO water filtration systems installed by Nam Viet

Common errors in industrial RO water filtration systems and how to fix them

| Featured | Reason | Handle |

| The system does not start after pressing Start | 1. Faulty circuit, blown fuse, wire source lost connection 2. Thermal protection element 3. Lack of water pressure | 1. Check fuses and circuits 2. Reposition the thermal protection element 3. Check the water supply |

| Input coil no open after power on | 1. Broken wire 2. Faulty coil 3. Coil loop | 1. Connect the wires 2. Replace coil, change ring |

| The pump runs but does not have enough rated capacity | 1. Opposite direction of rotation 2. Filter core is clogged 3. Air in the pump 4. Drain valve opens | 1. Reconnect the wire 2. Clean or replace the core 3. Push the air 4. Adjust pressure after discharge |

| Pump makes noise when increasing pressure | 1. Control coil or circuit 2. Mechanical coil error | 1. Check and replace the coil or electric circuit 2. Replace or repair the coil |

| Stopped due to lack of pressure | 1. Lack of source water 2. The core is clogged 3. Pressure adjustment error while discharging | 1. Check the active water pump move or not 2. Clean or replace the core 3. Adjust the pressure valve, keeping the pressure down 1.4 kgf/cm2 |

| The wastewater pressure ratio is incorrect | 1. Leaking pipes 2. None of the discharge coils trip | 1. Check the tube 2. Check and replace the discharge coil |

| Not enough pressure | 1. Pressure test tube is clogged 2. Vapor in the test tube 3. Pressure gauge error | 1. Check the tube 2. Push up steam 3. Replace pressure gauge |

| Poor water output | Dirty or clogged membrane | Wash the membrane with chemicals |

| Productivity is poor | 1. Dirty membrane 2. Supply water temperature changes | 1. Clean the membrane with chemicals 2. Make the temperature suitable |

| The performance of the RO system upon startup does not meet the initial design requirements | · Operate with higher flow than actually designed · The deposition process is clogged with scale and particles inside the RO system because the system operates at a flow rate that is too low compared to the design. · The process of pressure loss in pipes or points with valves | · Operate properly with design flow · Check whether the system startup and shutdown process is correct with reverse osmosis pressure · Check the cleaning process and chemicals used: is the process effective and do the chemicals affect the safety of the membrane? · Check the conductivity of the water to see if it complies with the design · Check the carbon dioxide (CO2) content in the microgas feed water which will enter the permeate, creating carbonic acid and increasing the permeate conductivity. · Check for application of chlorine and other oxidizing chemicals – this may indicate a potential oxidation process · Check rate calculations and confirm scale inhibitor dosage rates. |

| The amount of dissolved substances in the finished water is high | · Can arise in the RO system or due to a problem with the plant’s input water source | · If it is due to the plant’s input water source, prevent it from being used in the RO system and fix the error · If it is due to the RO system, check the osmotic concentration of the RO membrane. There may be one or several membranes with a higher osmotic concentration than normal. |

| The process of creating a biofilm layer on the RO filter membrane increases the microbiological criteria in the finished water | · The osmotic flow decreases when operating at a constant feed pressure, causing after a period of time bacteria to combine with the sludge and create a layer of microorganisms on the filter membrane. | · Install devices to monitor membrane pressure differences to detect problems · Regularly analyze microbiological indicators in finished water · Install automatic or semi-automatic membrane cleaning (CIP) systems |

Nam Viet ETC has many years of experience in RO water treatment. We are confident that we will bring customers the most effective and economical treatment solution.

Please contact us immediately for advice and support.

Hotline 0932562177

Bài viết liên quan

Drinking water treatment for pigs and issues to note

Drinking water for pigs in particular and water treatment in livestock farming in general is...

Pure RO bottled water filtration system

What is a bottled water filtration system? The bottled water filtration system is essentially an...

Commonly applied water disinfection methods

Water disinfection is a mandatory step in the drinking and drinking process. Natural water contains...