Boiler descaling or boiler descaling, applied when the furnace is clogged with scale, is necessary and must be done quickly, because this scale will become an insulating layer, reducing heat transfer efficiency. Causes fuel consumption and boiler pipe damage.

Benefits of boiler descaling

- Cleans over 95% of scale deposits in the boiler

- Reduces fuel consumption due to the heat-insulating residue layer

- Reduces the risk of pipe cracking and damage due to overheating.

- The boiler operates with high efficiency, economy and safety.

- Done day and night, including holidays.

Commitment when descaling the boiler

- Implementation time is quick, from 1-3 days depending on capacity and level of residue in the oven.

- Guaranteed to clean over 95% of sticky residue.

- Support checking related equipment and valves.

- Re-do the seal, seal faces, and pressure test to check for leaks before putting the furnace into operation.

- Free technical consulting support throughout the furnace’s operation.

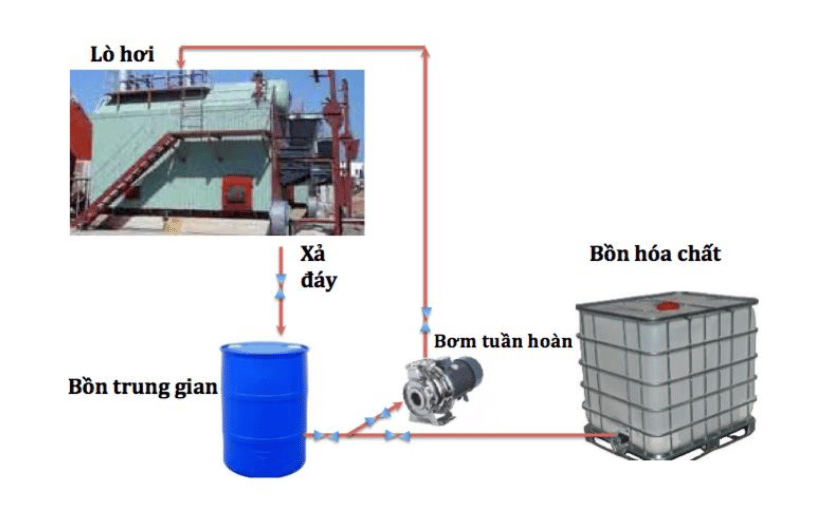

Diagram of adding boiler descaling chemicals

Boiler descaling process (click on video to watch)

– Discard the old water in the system, old water in the system often has chemicals and high pH which will reduce the effectiveness of cleaning chemicals.

– Pump new water into the furnace. Remember to only pump water until it reaches the pipe, do not pump too much water as it will reduce the concentration of cleaning chemicals.

– Install a circulating system to run the pump and check for leaks thoroughly before starting to pump in boiler scale cleaning chemicals.

Châm hóa chất tẩy cáu cặn nồi hơi

– Pump Corrosion inhibitor chemicals into the circulation system for at least 30 minutes and soak. The purpose is to protect the system from being corroded by cleaning chemicals.

– Pump cleaning chemicals into the system to be cleaned.

– Discard cleaning chemicals. The discharged solution is acidic with low pH and must be transported to a neutralization tank. Be careful not to put it directly into the tank biology will kill microorganisms.

– Pump neutralizing chemicals. The purpose is to neutralize the amount of detergent remaining in the system.

– Discard neutralizing chemicals.

– Use a pressure hose to wash mechanically to remove scale.

– Pump water into the furnace and check the pH. The supply water pH is equivalent to the water in the system, which means the cleaning chemicals are clean.

– Add maintenance chemicals to the furnace to limit corrosion and scale on the boiler.

– Reinstall the flanges, Pressure to check for leaks.

– Sign the project acceptance record.

Note: Hard residue or residue in hidden areas left over when running the furnace will automatically peel off, so in the first week of running the furnace, you must increase blowdown more than usual to remove the residue. Avoid clogging pipes and causing pipe fires.

The boiler tube rig was covered with limescale and after being cleaned

Water tube boiler backpack after chemical soaking and cleaning

Bài viết liên quan

Facility for scale formation and corrosion in boilers

Boiler scaling Scale buildup on the boiler fire tube Sludge in boilers is classified as...

Things to do and not to do at the boiler

Things to do at the boiler Regularly clean the soot from the blower fan Clean...

Heat transfer oil descaling chemicals

Heat transfer oil cleaning chemicals are widely used in cleaning burned residue and industrial lubricants...