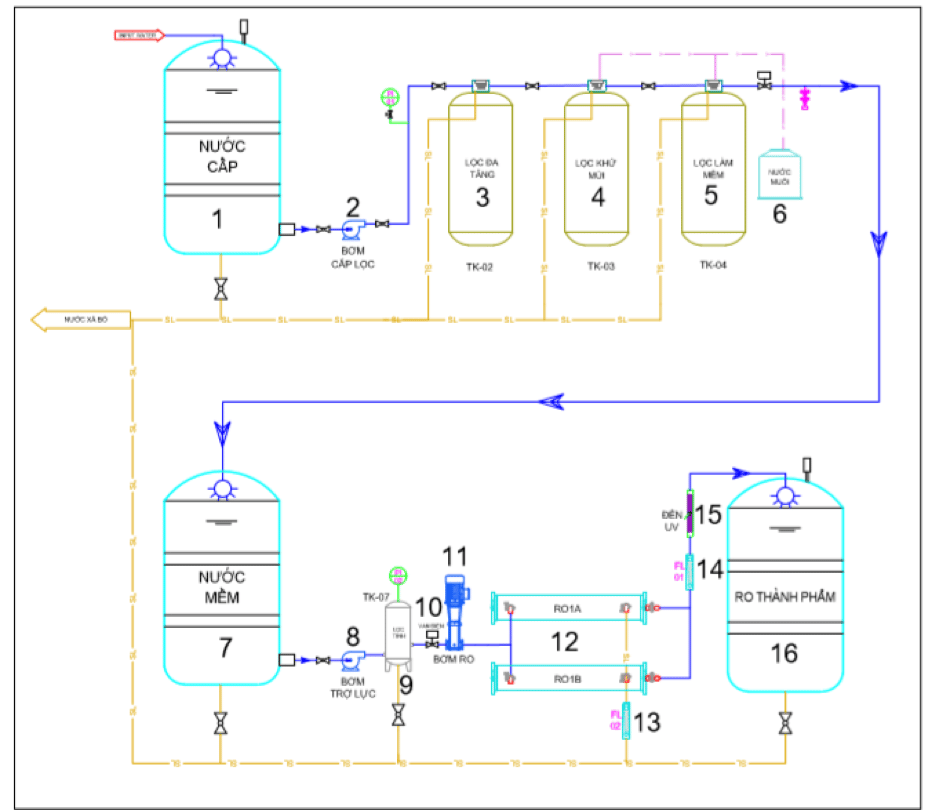

Technology diagram of industrial RO water filtration system

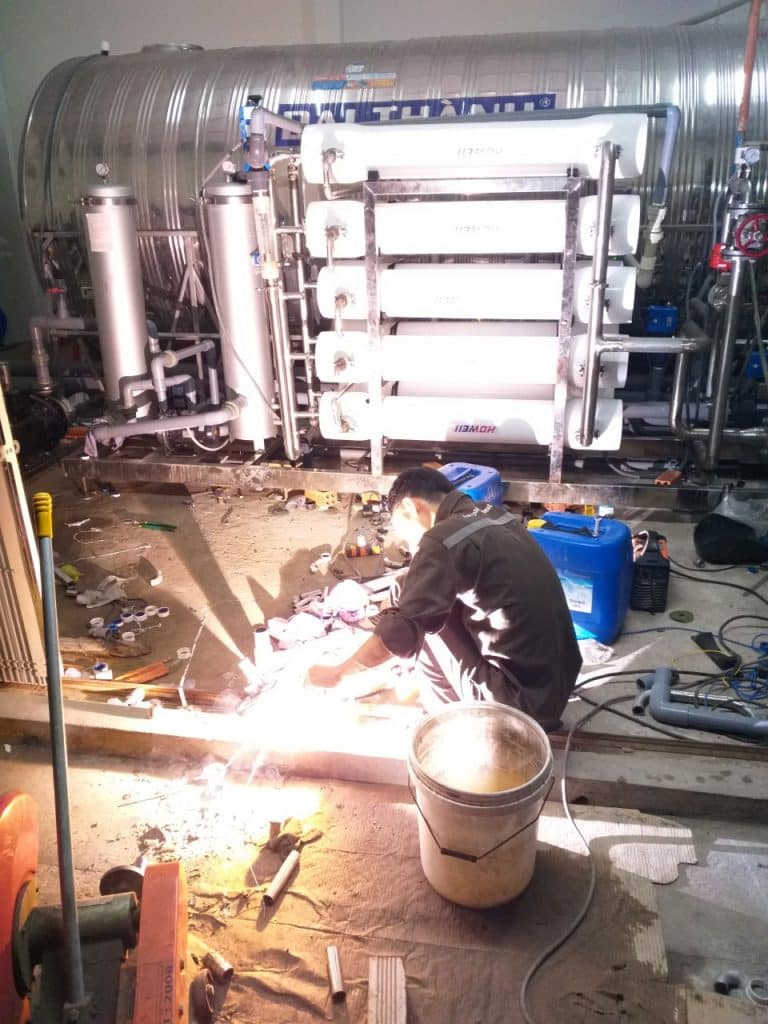

Industrial RO system model designed by Nam Viet ETC

Technology diagram of industrial RO system

1. Supply water tank

2. Filter supply pump

3. Multi-stage filter column

4. Deodorizing filter column

5. Softening column

6. Salt tank

7. Soft water tank

8. Power steering pump

9. Fine filtration

10. Solenoid valve

11. Booster pump

12. RO membrane

13. Measure the discharge water flowmeter

14. Measure the flowmeter to measure finished RO water

15. UV germicidal lamp

16. Finished RO water tank

Structure of industrial RO water filtration system

1. Pre-filtration equipment

This is the first stage of the water filtration process, helping to treat the raw part of the input water source, meaning the water will be removed from suspended substances and heavy metal chemicals. To do that function, this part is made up of a high-pressure pump system and large filter columns, also known as coarse filter columns.

Each filter cylinder will be structured and have different functions

– Filter column number 1: Contains sand, silica, and gravel, which is responsible for removing dirt, mud, and plankton impurities from the water

– Filter column number 2: Consisting of charcoal and activated carbon, they will remove toxic substances dissolved in water such as ammonia, sulfur, sulfur-based toxins, and phosphorus.

– Filter column number 3: This filter column has the function of softening water, reducing hardness to help prevent residue from clogging the RO membrane behind

– Fine filter column: Helps filter remaining suspended sediments of 5 Micron or more

2. High pressure pump in the system

To operate an industrial water filtration system, water pressure is needed to pass through all filters, especially RO filters. The high-pressure pump device will take on this task, designed extremely specifically, when operating, they create water pressure high enough for the osmosis process to take place quickly in the RO membrane. The pressure of an industrial pump can reach up to 200 – 230 PSI, with the ability to operate continuously 24/7.

Nam Viet Engineering installs RO water filtration systems at customers

3. RO filtration equipment in industrial filtration systems

After being processed through the pre-filtration stage, water will be transferred to the RO membrane filtration stage, which is considered the heart of the entire industrial water filtration system.

RO filter can remove TDS, impurities, viruses, and harmful bacteria in water. Depending on the quality of input water as well as filtration capacity, the supplier will arrange different numbers of RO filters. The more RO membranes there are, the greater the capacity to produce pure water

4. UV ultraviolet lamp

UV helps eliminate up to 99% of bacteria, helping to ensure safety when we use that water source in daily life. UV is a disinfectant but does not chemically change the taste or smell of water like chlorine.

5. Control unit

Besides the filter core parts and high-pressure pump, for the entire industrial water filtration system to operate smoothly, a suitable control system is needed. This system includes electronic circuit board systems, pressure gauges, meters displaying input and output water parameters. With these modern control systems, the water filtration process is completely closed implementation.

Nam Viet Environment Company constructs and installs industrial RO water filtration systems

Installation process of industrial RO water filtration system

Step 1: Receive customer request information

Step 2: Technical staff survey and consult directly with customers

Step 3: Research and provide solutions for RO filtration systems

Step 4: Installation and construction

· The device must be installed in a dry place, covered from sun and rain to avoid the effects of weather and humidity that can damage electrical equipment and contacts.

· The installation space must be spacious enough for the operator to operate

· Place the pure filter in the appropriate location and according to the manufacturer’s standards (The order of the filter columns is sand filter column → activated carbon filter column → water softener column → fine filter column → RO membrane)

· Devices must be placed on a flat, solid surface

· The purified water tank is not higher than 1.5m from the outlet of purified water and wastewater

· Install the input, output and power lines according to the circuit diagram instructions

Step 5: Check and operate the system and evaluate the water output after installation.

If you want to learn more about the RO system and common errors, please see

Nam Viet ETC with many years of experience handling boiler feed water, production and drinking water. We are confident that we will bring customers the most effective and economical treatment solution.

Please contact us immediately for advice and support.

Hotline 0932562177

Bài viết liên quan

Drinking water treatment for pigs and issues to note

Drinking water for pigs in particular and water treatment in livestock farming in general is...

Pure RO bottled water filtration system

What is a bottled water filtration system? The bottled water filtration system is essentially an...

Commonly applied water disinfection methods

Water disinfection is a mandatory step in the drinking and drinking process. Natural water contains...