Source of instant noodle wastewater generation

- Wastewater in the instant noodle industry arises mainly during the initial product processing process such as selecting and cleaning ingredients

- Product processing such as steaming, frying…

- Cleaning processing machinery and equipment, cleaning production factories…

- Wastewater generated from daily activities, cleaning, and bathing of workers and employees

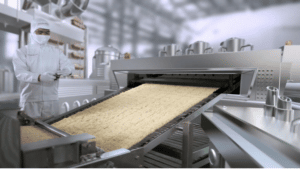

Producing instant noodles at a factory

Properties of instant noodle wastewater

- Instant noodle wastewater contains a lot of starch and shortening oil

- Wastewater generated from washing ingredients, cooking satay, and soup will contain a lot of grease and organic pollutants

- The concentration of TSS, BOD, COD, and bacteria components is quite high

- Instant noodle production wastewater contains salinity, color and especially starch

- Contains organic compounds (usually less toxic) originating from animals and plants

| T | Parameters | Units | Input value | QCVN 40:2011/BTNMT | |

| Column A | Column B | ||||

| 1 | PH | – | 5.5 – 6.5 | 6 – 9 | 5.5 – 9 |

| 2 | BOD5 | mg/l | 500 – 800 | 30 | 50 |

| 3 | COD | mg/l | 800 – 1300 | 75 | 150 |

| 4 | TSS | mg/l | 600 – 900 | 50 | 100 |

| 5 | Total Nitrogen | mg/l | 30-50 | 20 | 40 |

| 6 | Total Phosphorus | mg/l mg/l | 10-15 | 4 | 6 |

| 7 | Grease | 200 – 300 | 5 | 10 | |

| 8 | Total Coliform | MPN/100ml | 104– 105 | 3,000 | 5,000 |

Instant noodle factory wastewater pollution concentration table

Instant noodle wastewater treatment plan

- Does not make noise, does not cause unpleasant odors to the surrounding area.

- Does not affect the aesthetics and general activities of the factory and production area

- Simple management and operation, reasonable operating costs.

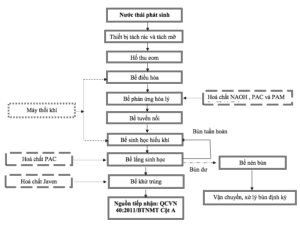

From the above characteristics and the requirements to be achieved after treatment, wastewater treatment technology includes the following main steps:

- Step 1: Use mechanical methods to remove large substances suspended in water, oil and grease and stabilize the flow of pollutants in water.</li >

- Step 2: Use physical and chemical methods to thoroughly treat COD, remaining grease and suspended solids, nitrogen, phosphorus… in wastewater li>

- Step 3: Use aerobic biological methods to remove toxic organic substances present in wastewater with the aim of reducing large amounts of organic pollutants in water such as BOD, organic substances, starch ….

- Step 4: Use disinfection method to kill harmful microorganisms in water. Ensure the output water meets wastewater discharge standards QCVN 40:2011/BTNMT for industrial wastewater

– Sewage sludge will be pumped to the sludge tank and treated according to regulations

Explanation of instant noodle wastewater treatment technology

- Wastewater generated from production and daily activities of factory employees will follow the collection network and flow to the centralized wastewater treatment system.

- Before entering the main treatment system, wastewater will be classified through a grease separator and flow through a garbage separator

- This process will help remove large amounts of oil and grease in wastewater and retain solid objects larger than 2 mm in size.

- After passing through the grease separator and garbage separator, the wastewater enters the air conditioning tank.

- Here the water source will be mixed evenly thanks to the aeration process supplied from outside. Because the water source is mixed, the pollution content and water flow will be evenly distributed throughout the tank, helping the process The back processing is most effective.

- Water from the conditioning tank, after a certain retention time, will be pumped by a submersible pump through the physicochemical reaction tank.

- Here the wastewater is pH balanced through the NaOH filling system to ensure high flocculation efficiency.

- After that, PAC coagulant chemical is added and mixed thoroughly thanks to the thrust of the pump and the mixing of the motor installed in the tank.

- Coagulants help destabilize “colloidal” residue particles and stimulate them to coalesce with other suspended residues to form flocs.

- Then flocculation aid A. Polymer will be injected. This A.Polymer has the effect of linking the flocs together to form larger sized flocs to improve the efficiency of pollutant removal.

- Wastewater from the reaction tank will be led through the flotation tank.

- At the flotation tank air is dissolved under pressure into the wastewater and pumped directly into the flotation tank.

- After entering the tank, air pressure is created and combined with water, it will be saturated with air bubbles smaller than 100 microns.

- Tiny air bubbles create a specific gravitational force that adheres to solid particles suspended in water and lifts the suspended particles to the surface of the liquid, forming a layer of floating sludge that is removed. removed by surface rake.

- This amount of boards is sent to the sludge tank.

- Wastewater after the flotation tank will be neutralized and flow to the aerobic tank.

- In this tank, aerobic microorganisms are very active thanks to the adequate oxygen supply from air blowers placed outside, and a favorable and stable living environment inside the tank due to adequate nutrient sources. nutrients in wastewater and microorganisms are added regularly.

- Aerobic microorganisms will use pollutants such as: BOD, COD, N., starch, and organic substances as food to grow and develop, leading to the elimination of pollutants in water, the mechanism of action of aerobic microorganisms is shown as follows:

The process of handling filial piety includes 3 stages:

Phase 1: The process of Oxidation of organic substances forms CO2 and H2O, part of the energy

C xH y O z + O2 => CO 2 + H 2 O + DH

Stage 2: VSV synthesizes new cells:

C x H yO z +.NH3 + O 2 => CO 2 + H 2 O + DH

Phase 3 Intracellular degradation:

C 5H 7 NO 2 + 5O 2 => 5CO 2 + 5 H 2O + NH 3 ± DH

- From the aerobic tank, the wastewater flows through gravity to the biological sedimentation tank with the addition of PAC sedimentation aid. Here, the sedimentation process occurs to separate the treated water and microbial biomass, which is sludge.

- Settled sludge will be pumped by 2 submersible pumps through the sludge compression tank. The compressed sludge will be sucked and treated periodically; The water separated from the sludge compression tank will automatically circulate to the equalization tank and continue to be treated.

- Wastewater from the water trough of the settling tank will automatically flow through the disinfection tank. Here Javen disinfectant chemicals will be injected, microorganisms remaining in the water source will be completely removed, and the treated water will meet discharge standards according to QCVN 40:2011/BTNMT, Column A.

Advantages of instant noodle wastewater treatment technology applied by Nam Viet

- Physical and chemical treatment combined with flotation is the most effective treatment process for suspended solids, remaining oil and grease and COD, N, P in wastewater

- Biological treatment process: is the process of treating synthetic organic matter, starch, BOD… achieve the highest efficiency. In the aerobic tank, the density of microorganisms per unit volume is high, so the organic load is high, thus the efficiency of organic matter treatment is higher and the ability to withstand shock loading is high. At the same time, due to the high density of microorganisms, the possibility of sludge generation is low

- Physicochemical technology combined with biology minimizes investment costs for treatment systems, saves investment costs and provides absolute treatment efficiency

- The system’s operating process is controlled completely automatically (can be controlled manually), which eases operational work, saves electricity costs, and ensures stable post-treated water quality. and meet the requirements.

Nam Viet Environmental Engineering Joint Stock CompanyNam Viet specializes in wastewater treatment and water supply. Customers need a quote or consulting support. Please contact us at hotline 0932562177

Bài viết liên quan

UASB tank in wastewater treatment

Introducing the UASB tank UASB stands for Upflow Anaerobic Sludge Blanket, roughly translated as reverse...

Wastewater treatment of carton paper packaging production

Origin of wastewater from carton packaging production Wastewater containing printing ink generated during the production...

Common Aerotank tank problems and how to fix them

Aerotank incidents during the operation of the WWTP often arise equipment problems such as pumps,...