Corrosion of the cooling tower system is a matter of concern with cooling systems.

Cooling systems are used for many purposes: office cooling; cooling for industrial equipment; Preserving products, raw materials…

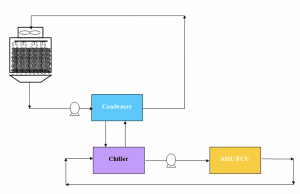

A cooling system usually includes: cooling tower system, chiller condenser, chiller system and piping system.

Structure diagram of the cooling system

Causes of corrosion in the Cooling Tower cooling tower system

- Water quality used: domestic indicators are not within the allowable limits for water used for cooling systems;

- System equipment: material structure and design do not meet requirements;

- Operation and maintenance process: no reasonable maintenance program;

- Influence of the environment: The cooling system, especially the cooling part, is often arranged outdoors, in direct contact with the environment, so there are problems of dust, impurities, and bacteria. The growth of living organisms will greatly contribute to system corrosion.

Types of corrosion in the Cooling Tower cooling tower system

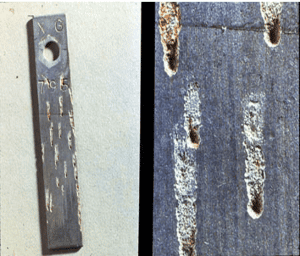

Pitting

It is a form of corrosion that creates irregular pitting.

Corrosion on metal surfaces.

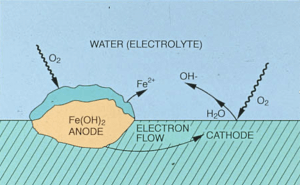

Electrochemical corrosion – Galvanic

- Galvanic corrosion occurs when two dissimilar metals come into contact with a solution and they can produce conductivity.

- When two metals are exposed to the same solution, the corrosion rate is faster.

- The electrochemical corrosion mechanism is illustrated as follows:

Electrochemical corrosion

Interstitial corrosion

- Crevice corrosion occurs in the crevice area.

- The solution inside a crack is similar to the solution inside an open hole in that the concentration of substances and acids is quite high.

Corrosion due to the influence of microorganisms

- Microorganisms in the water form a microbial film on the surface of the system.

- This membrane includes microbial communities and their secretions in polymer form.

- The types of microorganisms living in cooling systems can exist in different conditions, from aerobic species to anaerobic bacteria.

Anti-corrosion chemicals for cooling tower systems BSG 9000

Anti-corrosion chemicals for cooling towers provided by Nam Viet

- BSG 9000 is a mixture of organic phosphate and copolymer.

- BSG 9000 will limit residue formation through crystal breakage, complexation and dispersion.

- BSG 9000 is an organic-based corrosion and scale inhibitor.

- BSG 9000 is used to maintain organic phosphate levels at an acceptable concentration in cooling system water.

- The optimal level of treatment will depend on the conditions and operating parameters of the cooling system.

- In this regard, our techniques will provide the optimal level of processing suitable for each system.

- BSG 9000 dissolves well in water, does not corrode equipment, metering pumps, and steel containers.

- BSG 9000 can be introduced into the system directly by manual method or by dosing pump.

Benefits of anti-corrosion and scale chemicals for the BSG 900 cooling tower system

- No pollution, only contains organic compounds that are easily biodegradable

- Prevents the formation of insoluble salt deposits.

- Limit blockages due to dust from the air.

- Resistant to oxidizing biocides.

Learn about scale in the cooling system here

Nam Viet specializes in providing chemical water treatment solutions to prevent scale, corrosion, and kill microorganisms for Cooling Tower and Chiller cooling systems. If you need advice or support, please contact hotline 0932562177

Bài viết liên quan

Chemicals to kill algae and algae in the cooling tower cooling tower system

Microbial algae in the cooling system cause flow obstruction, reduce cooling efficiency and cause system...

Anti-scaling chemicals for Cooling Tower cooling tower systems

Cooling system scale is a matter of concern because of the efficiency and safety of...