Aerotanks apply activated sludge aerobic biotechnology to treat wastewater. This is an effective and commonly used method. Aerotank is applied in pig farming wastewater treatment, domestic and production wastewater treatment, food processing wastewater treatment

What is an Aerotank?

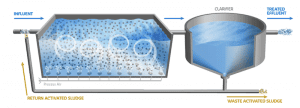

Aeroten tank is an artificial structure used to treat wastewater using aerobic biological methods, in which people provide oxygen and mix wastewater with activated sludge.

Aerotank operates on strains of microorganisms that have the ability to oxidize and mineralize organic substances in wastewater.

Aerotank structure

- The tank has a simple structure of a rectangular block with an air distribution system (air blower, air distribution tube) inside to increase the amount of dissolved oxygen (DO in water).

- Aeroten tanks have a height of 2.5m or more so that when aerated, the amount of air has time to dissolve in the water. If it is low, it will all explode without dissolved oxygen.

Types of Aerotank tanks

- Classification according to hydrodynamic mode: Push Aerotank, Mixed Aerotank and Mixed Aerotank.

- Classification according to the working mode of activated sludge: Aeroten has a separate activated sludge regeneration (activation) compartment or tank and one does not have a separate activated sludge regeneration compartment.

- Classification according to BOD load per gram of sludge per day: Aeroten high load, low load and medium load,

- Classification according to the number of steps in Aeroten (Aeroten construction has many compartments or corridors): Aeroten 1 step, 2 steps, 3 steps…

Traditional activated sludge Aerotank

The first traditional flow aerotanks used were long, narrow aerobic tanks. The amount of oxygen needed varies along the length of the biochemical reactor. Therefore, this system uses ventilation devices to ventilate the surface so that the amount of oxygen supplied is consistent with usage needs along the length of the tank.

Reactor tanks are usually rectangular in shape, with the activated sludge inlet and circulation entering the tank at one end and the mixed tank liquid (waste stream) exiting at the opposite end. The flow pattern is almost the same as a uniform flow system, with the distribution of fluid time depending on the length and width ratio of the tank, the mixture in the tank including oxygen supplied by the device, the substrates Available in inflow and outflow.

Gas distribution disc system in Aerotank tank installed by Nam Viet

Wastewater after the first phase sedimentation tank is mixed evenly with circulating activated sludge at the beginning of the Aeroten tank. The tank capacity is designed with a water retention time to aerate the tank from 6 to 8 hours when using the aeration system and from 9 to 12 hours when using a mechanical stirring device to aerate the surface.

The amount of air supplied from 55m3/1kg BOD5 to 65m3/1kg BOD5 needs to be eliminated. Sludge volume index usually ranges from 50 – 150ml/g, sludge age usually ranges from 3 – 15 days. The input BOD concentration is usually < 400mg/l, cleaning efficiency is usually 80 – 95%.

Aerotank activated sludge contact – stable

This system divides the reaction tank into 2 zones:

- The contact zone is where the conversion of organic materials in the input wastewater occurs.

- The stabilization zone is where the activated sludge circulating from the filter is aerated to stabilize the organic matter.

Because the concentration of suspended solids in water is quite high in the stabilization tank (equivalent to the concentration of circulating activated sludge), the total volume of the biochemical reactor (contact and stabilization zone) can be smaller, similar to as in a traditional sludge tank, while still maintaining the same sludge retention time. Therefore, this type of sludge tank is used to both reduce the volume of the reaction tank, or to increase the storage capacity of the traditional sludge tank.

In the contact area, the contact time is from 20 – 60 minutes (depending on the inflow flow). The recycled sludge stream usually accounts for 25 – 75% of the input wastewater stream for treatment. The volume of the stability zone accounts for 50 – 60% of the total volume of the entire system, with water retention time usually ranging from 0.5 – 2 hours, while the volume of the contact zone is 30 – 35% of the total volume. with water retention time of 4 – 6 hours depending on the circulating activated sludge flow. The treatment efficiency of this system usually reaches 85 – 95% of the ability to remove BOD5 and suspended solids from treated wastewater. Contact-stabilized sludge tanks are often used in the treatment of domestic wastewater with significant amounts of organic compounds in the form of solid molecules.

Aerotank tank is growing microorganisms

Aerotank has a higher load capacity

Wastewater entering the tank is highly contaminated, usually BOD > 500mg/l. The load on activated sludge is 400-1000mg BOD/g sludge per day and night.

Wastewater after preliminary treatment is mixed evenly with return sludge (sludge amount is about 10-20%) and then enters the Aerotank. Activated sludge concentration in the tank ≤ 1000mg/l. After 1-3 hours of aeration, 60-65% of BOD has been removed and the effluent water can reach grade C or near grade B.

This tank is often used to treat industrial wastewater from meat and dairy processing. Traditional or conventional tanks can perform prolonged aerobic and almost complete BOD removal. In tanks of this type, easily decomposable soluble organic substances will be oxidized first, then substances that are more difficult to decompose, or in colloidal form or small suspended particles, will be absorbed by microorganisms and then destroyed. subsequent decomposition.

Here, air is blown in continuously for 6-8 hours. Thanks to that, the ability to oxidize materials occurs very quickly. The gas supply system is distributed throughout the length of the Aerotank tank.

Complete stirred air Aerotank

Aerobic tanks with high aeration rates and complete agitation are relatively ideal for treating wastewater with high levels of pollution as well as high concentrations of suspended substances. Aeroten of this type will have a short working time. Shorten aeration time by operating at high F/M ratio, reducing activated sludge life (short water retention time in the tank). In the complete agitated Aeroten tank, wastewater, activated sludge, and dissolved oxygen are mixed evenly and instantaneously. Therefore, the concentration of activated sludge and dissolved oxygen is evenly distributed everywhere in the tank and leads to a uniform and highly effective oxidation process.

- The advantages of this technology are:

- Immediately dilute the concentration of contaminants, including toxic substances (if any).

- There is no overloading of tanks anywhere in the tank.

- Suitable for treating wastewater with high loads, high sludge volume index, and difficult-to-settle sludge.

Aerotank has a multi-step high load capacity

Wastewater after settling tank 1 is brought into the Aerotank by sections or steps, along the length of the tank (about 50-60%), circulating sludge goes to the beginning of the tank.

This type of tank supplies air along its length. Providing air this way will leave excess oxygen at the end of the Aerotank. However, Aeroten is built into many compartments so it can be easily fixed. Including horizontal multi-step Aerotank and vertical multi-step Aerotank.

High-load Aerotank with many horizontal steps

The tank length is very large compared to the width. In this tank, the incoming wastewater can be distributed at many points along the length, and circulating activated sludge is fed into the beginning of the tank. The aeration rate gradually decreases with the length of the tank. Intracellular degradation occurs at the end of the tank. Appropriate load is about 0.3-0.6kg BOD5/m3 day with MLSS content=1500-3000mg/l. Water retention time is 4-8 hours, F/M ratio = 0.2 – 0.4, sludge retention time is 5-15 days, sludge return 15-50%. BOD treatment efficiency is 85-95%, good output water quality.

Aerotank with multi-step high load capacity

This is an improved method of the conventional activated sludge method. Wastewater after primary sedimentation is put into the Aerotank at points corresponding to the F/M ratio, thus the need for oxidation gradually reduces. Portability is one of the advantages of this technology. This technology is used effectively for city wastewater. With the prolonged aeration method, the water retention time in the tank is large enough to oxidize the accumulated biomass. F/M ratio= 0.2 -0.4, MLSS= 2000-3500mg/l, HRT = 3-5h, load 0.5 – 0.9kg/m3 day, SRT = 5-15 days. The amount of sludge returned is from 25-75%. Ability to reduce BOD from 85-95%. The quality of water after treatment is good.

Compare the advantages and disadvantages of different types of Aerotank tanks

| STT | Tank type | Features | Advantages | Disadvantages | Applicable cases |

| 1

| Traditional activated sludge tank | Water retention time: 6-8 hours Air intake from 55m3-65m3/1kg BOD5 The age of mud is usually from 3 – 15 days | Simple Low cost Popular | Long processing time Large tank volume Processing efficiency 80-95%

| Wastewater treatment in residential areas, small enterprises,… |

| 2 | Contact activated sludge tank – stable | Water retention time is 4 – 6 hours The recycled sludge flow usually accounts for 25 – 75% | Reduces the volume of the reaction tank, or can increase the storage capacity of the traditional sludge tank. | Treatment of domestic wastewater with large quantities of organic compounds in the form of solid molecules. | |

| 3 | Aerotank has a high load capacity | Amount of sludge returned 10-20%. Loading capacity 400-1000mg BOD/gmud/day/night | Industrial wastewater treatment for meat and milk processing | ||

| 4 | Complete aerated and stirred Aerotank | High F/M ratio, Activated sludge lifespan. Short water retention time

| Immediately dilute the concentration of contaminants, including toxic substances (if any). There is no phenomenon of overloading the tanks anywhere in the tank. Suitable for treating wastewater with high loads, high sludge volume index, and difficult-to-settle sludge. | Treating wastewater with high levels of pollution as well as concentrations of suspended substances; high load, high sludge volume index, difficult to settle sludge..

| |

| 5 | Aerotank with high load capacity of many horizontal steps | Load 0.3-0.6kgBOD5/m3 day MLSS=1500-3000mg/l. Water retention time is from 4-8 hours, F/M ratio = 0.2 – 0.4, Sludge retention time is from 5-15 days, The amount of sludge returned is 15-50%. | |||

| 6 | Aerotank with multi-step high load capacity | F/M=0.2-0.4, MLSS=2000-3500mg/l, HRT=3-5h, Load 0.5 – 0.9kg/m3 day, SRT=5-15 days. The amount of sludge returned is from 25-75% | – High sludge return – Large load – Relatively low water retention time | City wastewater |

Aerotank calculation

Refer to how to calculate Aerotank tanks and tanks in the wastewater treatment system here

Nam Viet Environmental Engineering Joint Stock Company specializes in consulting, design, construction and installation of wastewater treatment systems, water supply, and chemicals boiler. If you need consulting support or a quote, please contact Hotline 0932562177

Bài viết liên quan

UASB tank in wastewater treatment

Introducing the UASB tank UASB stands for Upflow Anaerobic Sludge Blanket, roughly translated as reverse...

Wastewater treatment of carton paper packaging production

Origin of wastewater from carton packaging production Wastewater containing printing ink generated during the production...

Common Aerotank tank problems and how to fix them

Aerotank incidents during the operation of the WWTP often arise equipment problems such as pumps,...