Chemicals to prevent boiler scale corrosion

Harmful effects of scale and boiler corrosion

THarmful effects Boiler scale

- Consumes a lot of fuel due to poor heat transfer efficiency.

- Pipe breakage due to overheating.

- Increased machine downtime due to furnace repairs.

- Furnace repair and maintenance costs.

- Reduce boiler life.

- Dangerous to human life due to boiler explosion.

Harmful effects Boiler corrosion

- Iron contamination from water supply pipes and tanks.

- Reduces steam purity, affecting product quality.

- Causes clogging of siphons and valves due to rust.

- Damaged equipment must be stopped from working.

- Capital costs for repair and replacement.

- Maintenance requires a lot of time.

Image of boiler tube with deposits and corrosion

Cause of scale and boiler corrosion

Causes of boiler scale

- Hardness is the leading cause of scale buildup in boilers, which is also the reason why people often call boilers limescale.

- TDS Total dissolved solids in water, high soluble salt content increases the risk of scale buildup in the furnace

- Suspended TSS in water settles to the furnace surface. Evaporation of water in the oven is also the cause of scale

Causes of Boiler Corrosion

- pH that is too low or too high poses a risk of corrosion to the boiler. For iron and steel, scientists have found a safe pH threshold in the range of 10.5-12. Anything outside this range is not safe for the boiler.

- Oxygen dissolved in water combined with high temperature environment should speed up metal oxidation

- Chloride Cl- is an ion found in saline water and is also a strong corrosive agent in boilers

Solution to prevent scale and corrosion of boilers

Water softening system installed by Nam Viet

Control the quality of soft water supplied to the boiler

- Hardness is the main cause of scale formation in the boiler system when this water source is supplied to the boiler. If the hardness in soft water is not controlled well, exceeding the allowable limit (< 3mg/l) will cause scale deposits in the boiler.

- The water softening system (referred to as Softener) uses resin beads to exchange ions. The nature of the resin is to exchange ions in the form of RNa, the Na+ radical is very mobile, it will exchange with ions causing hardness in the water when the water is led through the system according to the reaction. After going through the softening system, the total hardness in the furnace water is < 3 mg/l. Controlling the total hardness in furnace water will help the furnace limit scale, increase furnace life, and minimize repair and damage costs.

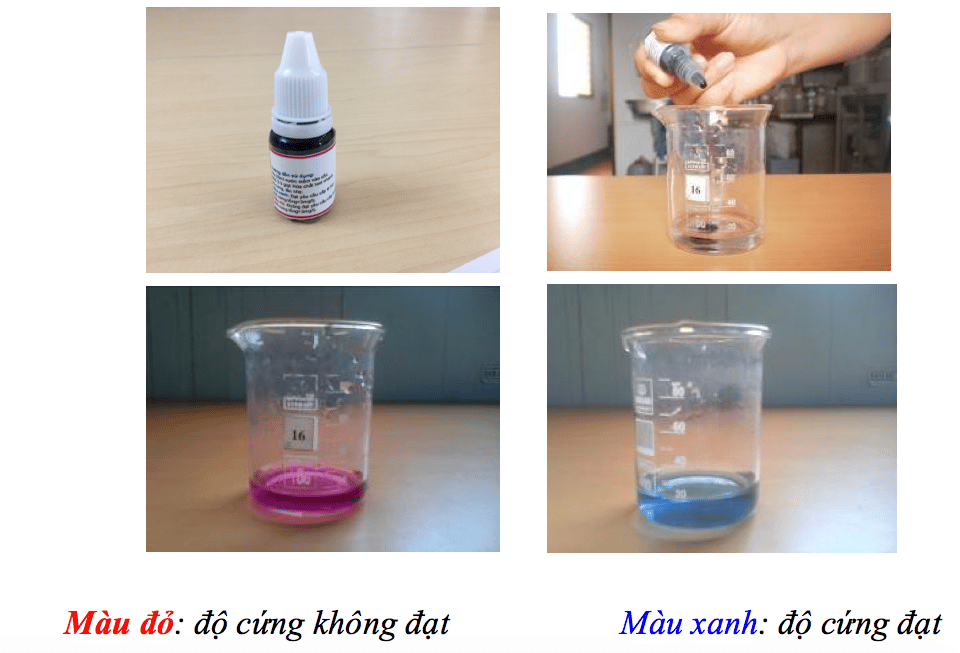

- To ensure that the furnace water hardness is within control limits, your company needs to periodically check soft water hardness once per shift using Nam Viet’s hardness reagent.

The steps to test soft water hardness are as follows:

– Step 1: Take 10 ml of soft water sample (water after softener)

– Step 2: Add 01 drop of Nam Viet hardness reagent to the soft water sample.

– Step 3: Shake gently to dissolve the reagent in water

– Step 4: Look at the color: If the water is red, the hardness is not satisfactory, if the water is green, the hardness is satisfactory. When detecting that the water does not reach hardness, regenerate the softening system. Make sure to provide enough salt for the system regeneration process to be effective.

Use maintenance chemicals to prevent boiler scale corrosion

To improve the operating efficiency of the boiler, your company should use chemicals to inhibit corrosion and scale from occurring in the system, reducing fuel waste as well as damage incidents. boiler caused by water source of poor quality. The amount of maintenance chemicals used monthly depends on the current state of the boiler system and the quality of water supplied to the boiler. Scale inhibitor chemical BW9001. The main ingredient is sodium tripolyphosphate. The scale inhibition reaction is as follows:

10Ca2+ + 6PO43- + 2OH– → Ca3(PO4)2.Ca(OH)2

(Calcium hydroapatite is in suspended form, when blowdown will follow the water out) Corrosion inhibitor BW9002. The main ingredient is sodium sulfite, which will expel dissolved oxygen in water according to the reaction:

2Na2SO3 + O2 → 2Na2SO4

Using maintenance chemicals combined with well-treated boiler feed water quality will gradually bring the indicators of sulfite, phosphate, phenol alkalinity, and hardness to control limits, helping to increase the life of the boiler and reduce the incidents and risks in the production process, save fuel, reduce repair costs.

Chemicals to prevent scale and corrosion of boilers are provided by Nam Viet

If you want to find cleaning chemicals for boilers that have scaled up, please click come in

Nam Viet is a unit specializing in providing water treatment solutions and anti-scale chemicals for boilers. With more than 10 years of experience and services for more than 100 factories with many big brands, we are confident that we will bring customers the best solutions.

For further details, please contact Hotline 0932.562.177